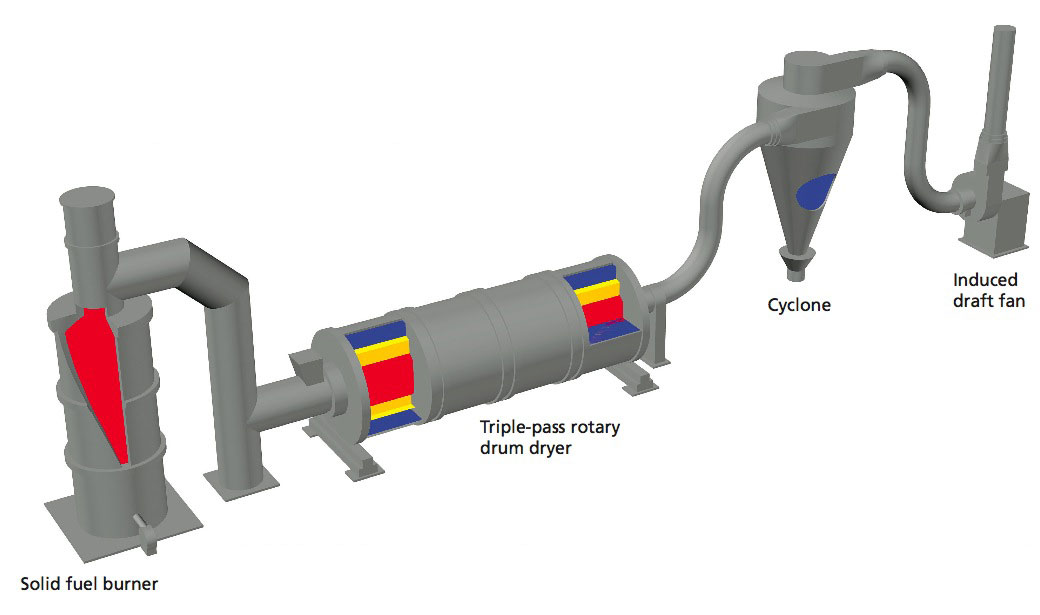

Jackson has been involved in the drying of wood shavings since 1979. In that time, we have seen a number of different methods employed, with varying degrees of success. Our experience has shown that the most cost-effective and efficient method for drying wood shavings is the use of triple-pass drum dryers (click for a brochure), such as those pioneered in the 1920s by the Arnold Dryer Company of Milwaukee (later a division of the Heil Co.). New drum dryers are now built by Baker-Rullman Mfg. and others, and reconditioned used units are also a popular and economical option when available.

This simple, direct, and highly effective method of drying has been successfully applied in the dehydration of a wide range of materials; and has proved to be the ideal method for drying shavings. The drying drum features an expanding cross-sectional area and a compound showering flight pattern which guarantees maximum exposure of all particles to the drying medium. The velocity and temperature of the air stream are different in each of the three passes to suit the changing rates of evaporation as the moisture content of the shavings decreases.

Image courtesy of Baker-Rullman Mfg.

Image courtesy of Baker-Rullman Mfg.

Traditionally, these drum dryer systems have been fired with either fuel oil or natural gas burners. This is still necessary when the downstream process(es) require perfectly clean conditions, such as products for human consumption.

However, whenever possible, the most economical choice is a biomass solid fuel Webb Burner®. These burners offer very significant advantages:

Jackson has been a leader in the wood shaving industry for over 60 years. In that time, we have manufactured over 350 wood shaving mills, and have worked with over 100 customers to set up entire shaving plants. We bring this unparalleled depth of experience to every customer -- whether building one of our smallest shaving mills for a one-man owner/operator just getting started, or designing, installing, and starting up a complete plant layout "from scratch."

We can:Afterward, we follow up to make sure everything is right; and provide on-going support for replacement parts, and service work if necessary. We would be happy to discuss your project -- simply give us a call at +1 (715) 926-3816, or see the "Contact Us" page.

|

Firefly AB P.O. Box 92201 SE-120 09 Stockholm Sweden |

Phone: +46 (0)8 449 25 00 In North America call: +1 (847) 948-7099 |

|

Flamex Inc. 4365 Federal Drive Greensboro, NC 27410-8116 |

Phone: +1 (336) 299-2933 Fax: +1 (336) 299-2944 |

|

GreCon, Inc. 15875 SW 74th Avenue Tigard, OR 97224-7934 |

Phone: +1 (503) 641-7731 Fax: +1 (503) 641-7508 |

|

HansenTek Division Neola Corporation 4141 Sladeview Crescent Unit 18 Mississauga, ON L5L3E1 Canada |

Phone: +1 (905) 607-5780 Fax: +1 (905) 607-5779 In the United States, contact: Robert White Industries, Inc. 9073 Jade Court N Lake Elmo, MN Phone: +1 (651) 731-6647 |

Proposition 65 WARNING: Cancer and birth defects and reproductive harm - www.P65Warnings.ca.gov.

Proposition 65 WARNING: Cancer and birth defects and reproductive harm - www.P65Warnings.ca.gov.